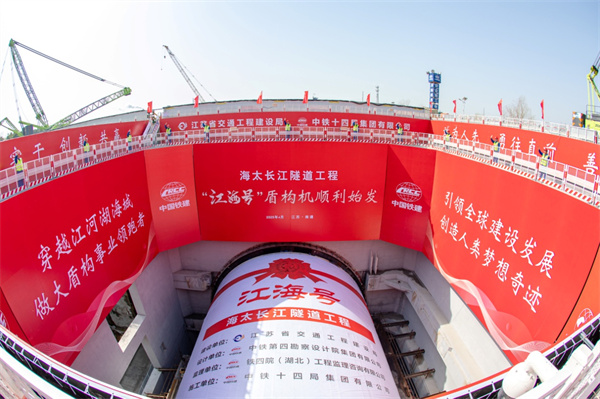

China has deployed a giant self-developed tunnel boring machine (TBM) for the construction of the world’s longest underwater highway tunnel. The machine, named “Jianghai”, has a maximum excavation diameter of 16.64 meters. It is being used in the construction of the Haimen–Taicang Yangtze River Tunnel in east China’s Jiangsu Province.

China deployed a giant self-developed tunnel boring machine for the construction of the world’s longest underwater highway tunnel. [Photo/sasac.gov.cn]

The tunnel, designed by China Railway Siyuan Survey and Design Group Co., Ltd. and constructed by China Railway 14th Bureau Group Corporation Limited, both subsidiaries of China Railway Construction Corporation Limited (CRCC), serves as a key project in establishing a major trans-river road link beneath China's longest river, connecting Haimen in the city of Nantong with Taicang in the city of Suzhou, facilitating seamless connectivity between the two cities. Stretching approximately 39.07 kilometers in total, the tunnel includes an 11.185-kilometer underwater section, with 9,315 meters to be excavated using a TBM. It is designed as a six-lane, bidirectional highway with a speed limit of 100 km per hour.

This engineering project sets multiple records. It is China’s first zero-carbon tunnel, and the first to feature a dedicated rescue vehicle access tunnel, a segmented smoke extraction system and double-deck composite interlocking (DDCI) technology.

During the design phase, over 60 thematic studies were conducted on tunnel structure, waterproofing and fire resistance, disaster prevention, green and low-carbon solutions, smart construction and maintenance.

Navigating through complex geological formations beneath the riverbed, including layers of silt and fine sand, the tunnel will reach a maximum depth of 75 meters, subjecting it to immense pressure which is equivalent to 75 tonnes per square meter. These extreme conditions demand high levels of durability and precision in cutterheads, mud circulation systems and seal components.

Installation underway in the tunnel construction site [Photo/sasac.gov.cn]

To tackle such difficult construction conditions, the “Jianghai” shield machine is equipped with innovative technologies, including a high-pressure, high-flow central flushing system and an intelligent monitoring system with retractable cameras to enable real-time monitoring of cutterhead wear. It also features dual slurry injection to improve efficiency. Meanwhile, DDCI technologies at the joints of tunnel segments are used to improve the tunnel’s structural performance in soft soil environments.

The tunnel will play a pivotal role in promoting regional integration within the Yangtze River Delta and the high-quality development of the Yangtze River Economic Belt, said CRCC.

(Executive editor: Wang Ruoting)